Layer-by Layer — Printed Proof:

Case Study: Beau's Story — How it All Came Together

Compassion, when witnessed, tends to elicit sympathy in others. Doing something nice for someone else is not usually a difficult task, yet the smallest acts of kindness can have the most significant impact. This story is a culmination of several acts of kindness and the significant impact they had on a family in Illinois and potentially on many other families. Eighty-five miles north of Springfield lies the bustling suburb of Eureka, where Logan and Kara live with their twins, Beau and Brooklyn. Born at 28 weeks, Beau weighed just 1 pound 11 oz. and required to have an oxygen tank with him at all times.

The Problem

Logan was looking for someone to help him lighten an oxygen tank bracket for a Radio Flyer wagon for his son, Beau. At the time, Rick Willardson was the president of the North American Society for the Advancement of Material and Process Engineering (SAMPE) forum. Rick’s former employer/boss, James Richmond, had reached out to see if he knew of anyone who could help his nephew, Logan. Rick shared a video on the SAMPE member forum, and one of our engineers, Chantelle, happened to find it. She was moved and shared it with NW Rapid’s owner, Heather, and the team’s other engineer, Ken.

The Solution

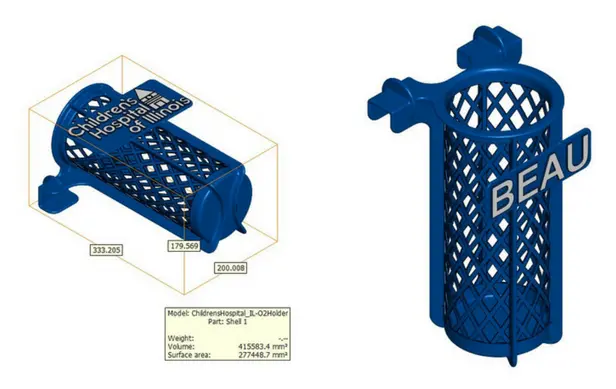

“What can I say: stories about kids and pets get to me — right in the old ticker,” Ken shared. “When Chantelle brought this story to us, it struck a chord (C minor to be exact), and I knew I had to get involved.” After shedding a few tears (mostly from Ken), they got to work on a design. Ken made two versions of the bracket, as the first did not meet the strength requirement — it was a little too flexible for Ken's liking. Below are the two variations. On the left is the first iteration and on the right is the second, more stable design.

After Beau’s bracket was a success, Logan’s desire to make life better for others prompted him to connect with Advanced Ag Concepts. They were compelled to help and ultimately worked with Logan to create five additional brackets, which they fitted to five Pathfinder Wagons donated by Radio Flyer. All of this began with two parents who wanted to improve their son’s life.

The way life comes together is awe-inspiring. That the stars aligned to make this happen is nothing short of amazing and that so many people stepped up to help is beyond encouraging. (Oh, what we can do when we work together!) We were fortunate to have the ability to be involved in this little man's life, hopefully making it better in the process.

Bringing Ken's Design to Life

Cameron, our SLS Operator, demonstrates the process of breaking out the bracket from what we lovingly refer to as “cake.” After we print a design, we break away the unsintered powder, which can be recycled and, in some cases, reused. Have you ever wondered how our machines work after the lasers sinter the powder? Check out our video below.

For more information, please don't hesitate to contact us at or request a quote and upload your file today!