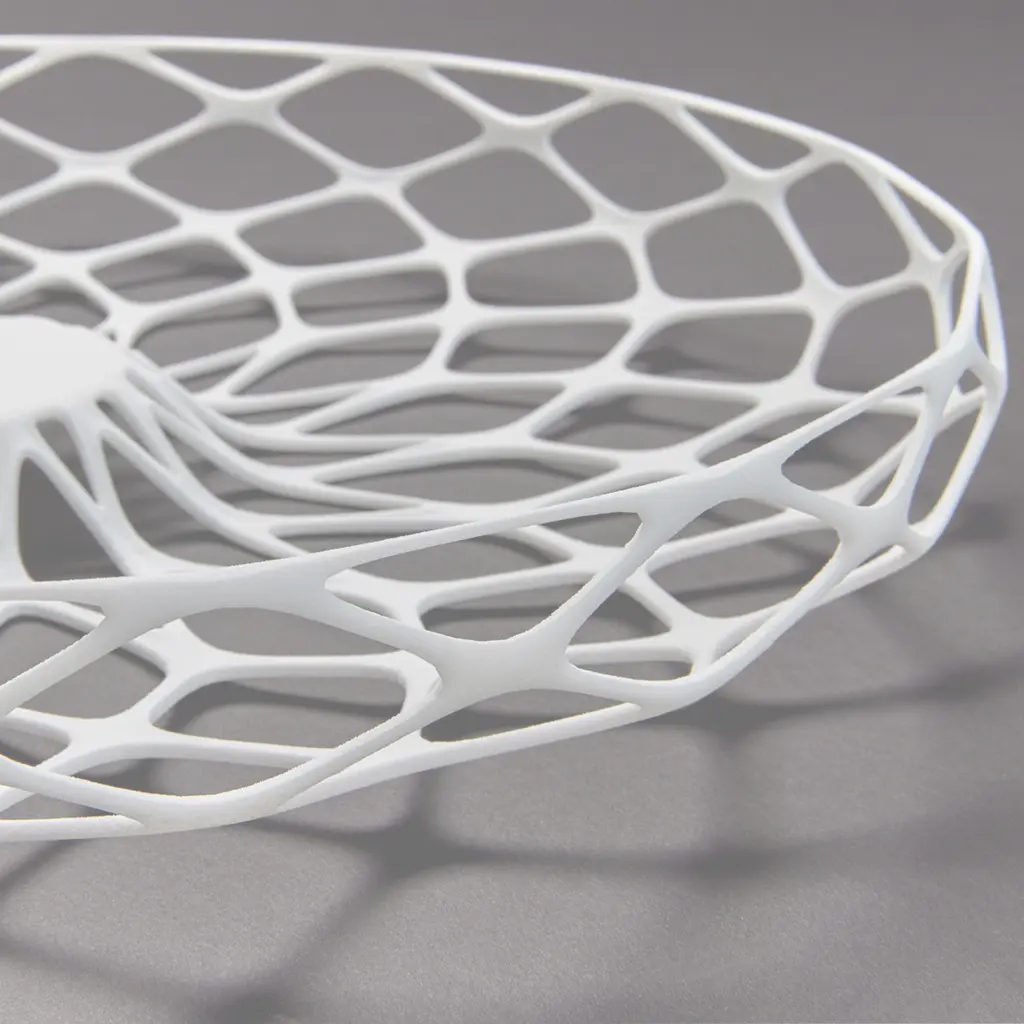

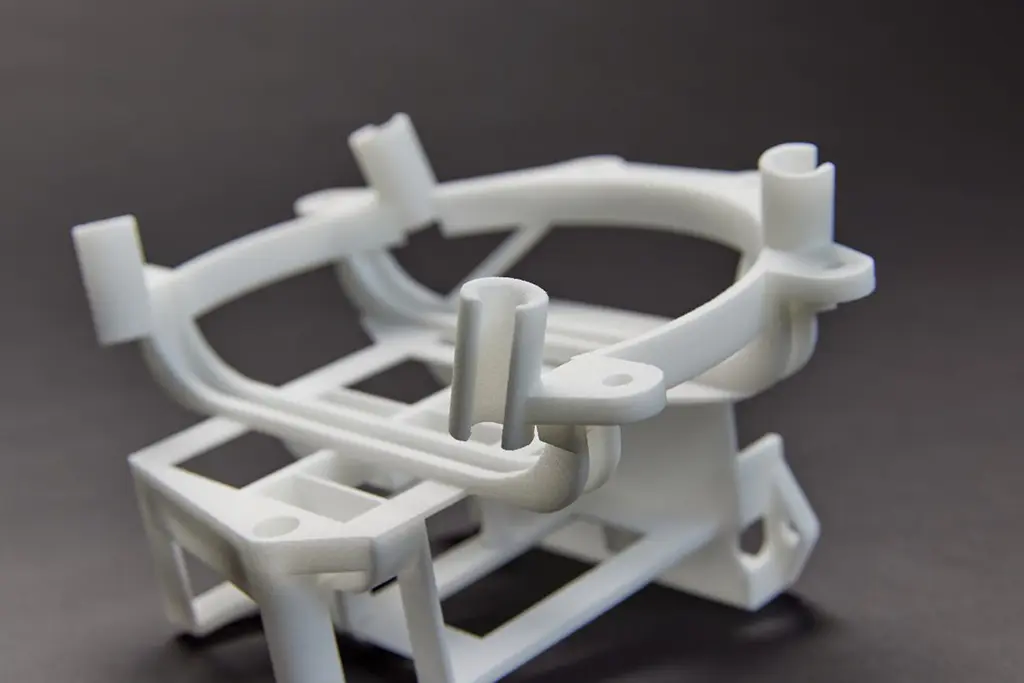

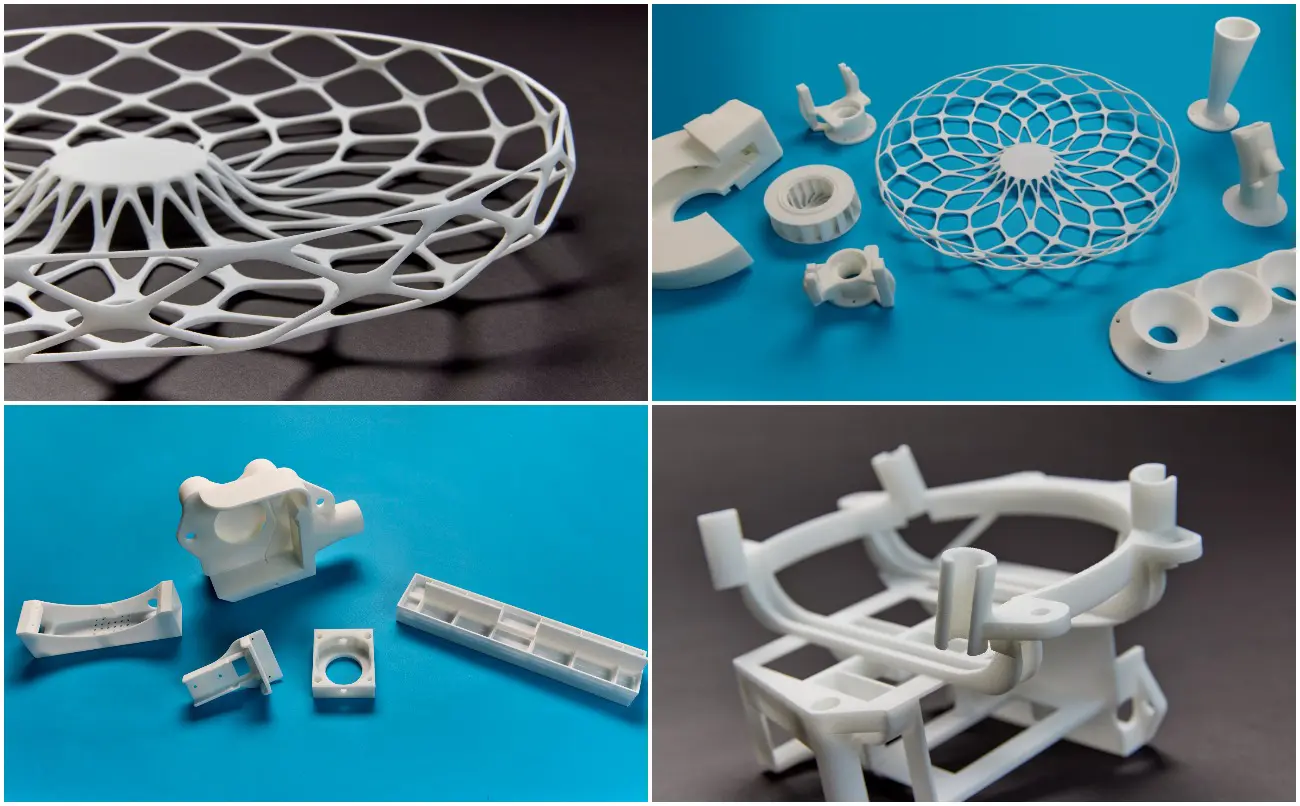

High-quality Laser Sintering (SLS) Production & Prototype Parts

With exceptional detail and professional finish. Let us help you bring your next big idea to life by getting your 3D CAD file to reality. SLS is a straightforward solution for complex designs, allowing you to go from powder to production in just a few days.

- Build directly from your CAD file

- Lightweight, structurally sound, complex parts

- Cost-effective

Our Vision & Mission

Dedicated to being the premier provider of rapid prototyping and production parts, utilizing the latest manufacturing techniques. Through superior process control, operational excellence, and unmatched customer service, we are building a legacy business that will serve thousands of customers for generations to come.

Innovation

Transforming ideas into reality faster than ever, enabling rapid prototyping, personalized manufacturing, and breakthroughs across industries from healthcare to aerospace.

Growth

3D printing is accelerating worldwide, driving new levels of efficiency, customization, and scalability across sectors and reshaping how products are designed, produced, and delivered.

Integrity

Delivering consistent quality, protecting intellectual property, and upholding ethical standards—building trust with clients, partners, and the market through transparency and accountability.

Collaboration

Together, we bring imagination to life—fusing your vision with our SLS 3D printing expertise to craft bold, original creations that push the boundaries of what's possible.

Our Expertise

Prototyping

SLS enables our team to transform your CAD data into a 3D prototype model without the need for molds or tooling.

Manufacturing

Layer by layer, our machines will print your parts faster than other manufacturing methods using lasers (yes, lasers!).

Finishing

No part is too complex with the variety of SLS part finishing techniques we offer to meet your project needs (trust us, we’ve seen a lot).

Materials

NW Rapid Mfg's SLS systems create fully functional prototypes and lightweight products of varying complexity using polyamide materials.

Expert Guidance

SLS Nylon Materials

The choice of selective laser sintering material depends on the specific design parameters of your application.

Materials

NW Rapid Mfg's SLS systems create fully functional prototypes and lightweight products of varying complexity using polyamide materials.

1 NYLON 12 | PA2201 Standard

- Color: White — develops a patina with air exposure, that does not affect its mechanical properties

- Ideal for most applications

- Used for fuel and liquid storage

- Exceptional chemical, fuel, and UV-resistant

- FDA certified (21 CFR §177.15009(b)) food safe, except for alcohol

- Melting point around 325°F

- No porosity with wall thicknesses ›1.5 mm (0.060")

- Can be tumbled, dyed, painted, glued, drilled, tapped, and machined

2 NYLON 12 | PA615-G5 Glass Filled

- Color: Eggshell — slightly creamy white

- Strong and durable

- Excellent dimensional stability

- Popular for tooling applications

- Produces a very heavy part as compared to all the other materials

- Contains a 50% fill of glass beads

1 NYLON 12 | PA2200 Ultra-White

- Color: Bright White — with a Titanium Dioxide Whitener

- Durable and rugged

- Chemical resistant

- Economical

- Melting point around 325°F

- USP Class VI certified for biocompatibility (non-toxic to human cells)

- Highly workable for secondary operations

- Can be tumbled, dyed, painted, glued, drilled, tapped, and machined

2 NYLON 12 | PA603-CF Carbon Fiber Filled

- Color: Gray/Black

- High tensile strength

- Suited for applications where a high heat tolerance, strength, and resistance to wear are of paramount importance

- Superior stiffness factor compared to High Performance Nylon 12

- Extreme smoothness when processed with our secondary finishing operations

3 NYLON 12 | PA620-MF Mineral Fiber Filled

- Color: Off-white

- Strong and durable – lighter when compared to glass-filled materials

- Good dimensional stability without the brittleness of carbon fiber

- Greater mechanical stability than unfilled materials

4 NYLON 12 | PA606-FR Fire Retardant

- Color: White

- Mechanical properties are similar to standard Nylon 12

- For applications where FAR certification is required (meets FAR 25.853 60 second burn specification)

- Suitable for interiors of aircraft, automotive, and other commercial transportation

- Excellent for laboratory ventilation and air handling

- Parts will exhibit a smooth surface finish and sharp feature detail

5 NYLON 12 | ALUMIDE® Aluminum Filled

- Color: Metallic silver appearance

- High stiffness

- Superior dimensional accuracy

- Good thermal conductivity

- Aluminum powder creates a product that is somewhat brittle – not recommended for structural applications

- Easy post processing via machining, grinding, and milling

- Secondary polishing processes provides a surface with a metallic-looking finish

- WARNING! This product should not be used in any application where contact with foodstuffs would be possible

6 NYLON 12 | PA640-GSL Carbon Fiber/Glass Filled

- Color: Dark Grey

- Carbon fiber increases the dimensional stability

- Hollow glass beads add increased durability

- Very lightweight

- Developed for the UAV industry

1 NYLON 11 | PA850-BLK Black

- Color: Black

- For applications that require slightly higher tensile strength at break, along with a higher elongation factor

- All-weather performance, it excels in extreme climates

- High-impact and high-pressure resistance at sub-zero temperatures

- Low coefficient of friction

- Not bio-compatible

2 NYLON 11 | PA840-GSL Carbon Fiber/Glass Filled

- Color: Dark Grey

- Carbon adds dimensional stability

- Hollow glass beads Increase durability over unfilled Nylon 11

- Additional flexibility with Nylon 11-based material

- Very light compared to other materials

- Electrically conductive, due to carbon content

- Specifically developed for the UAV industry

For details specific to your project give us a call us at 503-434-8557.

Get A QuoteOur Process From File to Finish

From concept to creation, we guide our clients through every step of the SLS 3D printing process to ensure efficient, high-quality results.

Establish Your Goal

To get the most out of your 3D-printed prototype, it's essential to define its goal – whether you're testing fit, function, or visual appeal. Knowing the purpose helps us guide material choices, finishes, and print settings to match your needs.

Create a CAD file

A CAD file is the foundation of any successful SLS 3D-printed project – it defines the geometry, dimensions, and details that guide the printing process. To ensure the best results, we offer design guidelines and support to help you prepare a CAD file optimized for printability, material behavior, and your specific application.

Development Phase

Our engineers review your CAD file and discuss options with you if needed. Once the 3D CAD file is approved, it is sliced into cross-sections or layers, each 0.10-0.15 mm thick.

The Printing Begins

The SLS machine heats the plastic powder to a temperature close to its melting point. The laser passes over the build platform and selectively melts one cross-section layer. The machine lowers the bed of the build chamber, and the recoater applies a new layer of material across the build platform, repeating these processes until the design is complete. Our machines build at a rate of about 10-15 mm per hour.

The Finished Part

After the powder cools, a technician removes the parts from the "cake" of powder, and each part is bead blasted to remove excess powder. Then, depending on the desired final results, it's off to finishing and delivery.

Frequently Asked Questions

NNorthwest Rapid Manufacturing wants to ensure you create a successful engineering design for 3D printing. These FAQs will help answer some frequently asked questions about the SLS process and designing for SLS printing.

1 Is SLS Only Used to Make Prototypes?

No. For example, thousands of our parts have been produced as production parts for installation on UAVs. These parts have amassed over 800,000 hours of flight time.

2 Can SLS Parts Be Produced Overnight and Delivered Within 24 Hours?

Technically, yes. There have been exceptional circumstances under which we could provide local orders within 24 hours, but that is not the standard. We will inform you of our turnaround time when you submit a quote or if you contact us.

3 What Is the Correct Name for The Selective Laser Sintering (SLS) Process?

There are a variety of terms. The industry has promoted the term "Additive Manufacturing" as a standard. Other terms include 3D Printing, SLS Manufacturing, Additive Manufacturing, Rapid Manufacturing, Selective Laser Sintering, SLS Prototyping, Rapid Prototyping, Short-Run Manufacturing, Limited-Run Manufacturing, 3D Prototyping, Direct Digital Prototyping, Direct Digital Manufacturing, and Desktop Fabrication.

1 Can I Print Any Design?

Almost, some designs are better than others. Please email your CAD file, and we personally review your design and will let you know if there are any concerns.

2 Is There a Way to Make Parts FDA-Compliant for Use with Food?

Yes! Our PA2201 Nylon 12 material is FDA-compliant for direct contact with food.

3 Are SLS Materials RoHS Compliant?

Certain materials have restricted use in newer electronic and electrical equipment. For more information, consult the RoHS (Restriction of Use of Hazardous Substances) regulations Statement of Compliance—RoHS and WEEE Directives.

4 Is NW Rapid ITAR registered?

Yes! We can enter into ITAR compliance agreements as necessary.

4 Are Biocompatibility Certificates Available for the Materials Used in the SLS Process?

Yes. NW Rapid has a Biocompatibility Certificate on file for PA2200 Nylon 12. We can provide this certificate upon request by contacting us at make@nwrapidmfg.com

Unlock The Power of SLS Printing Today!

Join our satisfied customers who have transformed their projects with our innovative solutions.

Location

11020 SW Durham Lane

Building F/1

McMinnville, OR 97128

Open Hours

Monday-Friday: 7AM – 4PM

Get in Touch Today!

Whether you're ready to print or just exploring possibilities, reach out—we'd love to hear from you.