Layer-by Layer — Printed Proof:

Case Study: 3D Printing Solutions for a Local Screen-Printing Company

From beer to salad dressing, if it comes to you in a glass, plastic, or metal container, you could be holding a tiny work of art brought to life by a custom screen-printer. Founded more than 25 years ago, Superior Screen Systems (Tri-S ) specializes in printing on bottles and containers of all shapes and sizes. The magic happens in an impressive facility, always smelling of freshly painted walls nestled in an expansive business complex in Tualatin, Oregon. With a team of 25 employees, Tri-S can print between 15,000 and 20,000 bottles per day. Their clients are primarily West Coast-based companies, though their reach is nationwide. You may recognize some of their more well-known clients above.

Working with recyclable, non-toxic, organic inks, Tri-S is committed to reducing its environmental footprint. They recycle as much as possible, use energy-efficient lighting, and have transitioned from curing their screen-printed ink with inefficient ovens to a speedy UV-light curing process. Fun fact: they even purchased wetlands to conserve and protect them from development. (Nice folk!)

The Problem

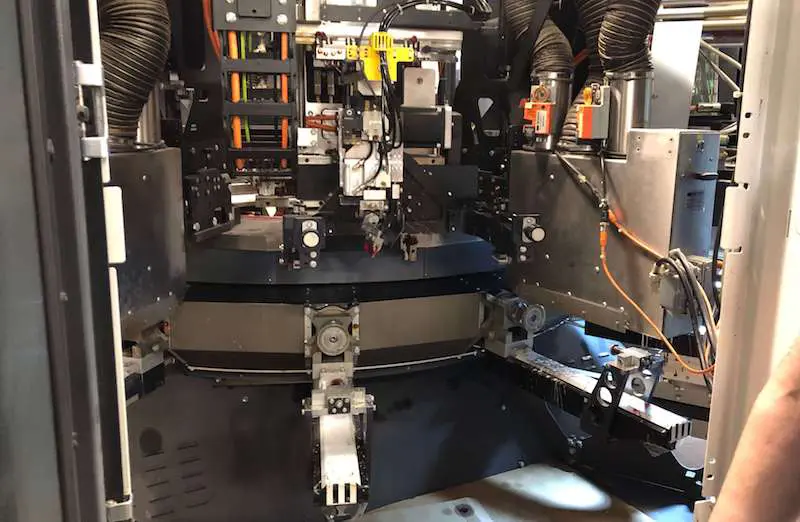

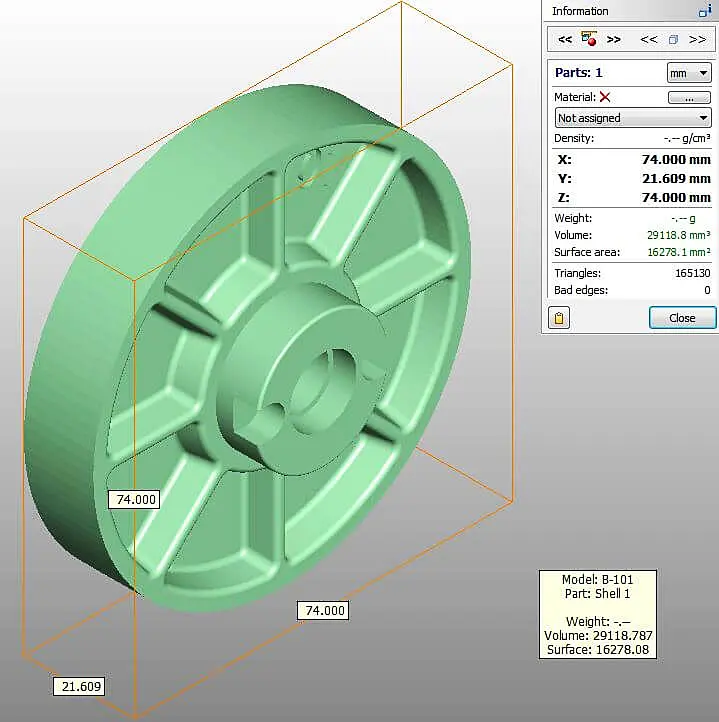

Working with a German company, they had a custom screen-printing machine built that holds up to 15 bottles at a time. Like most businesses, Tri-S was seeking a way to reduce some of its costs while maintaining quality and increasing production speed. One area they wanted to change was the manufacturing process of the base cups that hold the bottles in place during screen printing and curing. Each bottle has a different diameter and radius, so the base cup must be a perfect fit for its bottle mate.

In the past, they had a complete set of tooling – 16 base cups and nose cones — manufactured by the same German makers of their printing machines. Since each bottle differs in shape and size, a bottle will rarely fit in a set already on site. Moreover, even bottles of the same style can vary in size due to the inherent properties of glass and the molding process used to create them. To accommodate new bottle shapes and sizes, they would manufacture a steel set for every style of bottle at a cost of approximately $8,000, with some costing upwards of $20,000. It typically takes 8 weeks to receive a set, which, in manufacturing, is a relatively long turnaround time.

An alternative was to look a little closer to home, and they went with a machine shop just down the street. They developed a similar design consisting of steel and polyurethane. While the cost did decrease somewhat, the turnaround time remained relatively unchanged. In addition to the delay in producing new sets, there was the issue of the steel’s fragility; if a cup were to be dropped, it could alter the shape of the base, and bottles would no longer fit.

The Solution

We had the opportunity to pick John Chapman’s brain at the Tri-S facility. The company’s President and CEO, John knows the ins and outs of the business. He saw the challenges with their current base cup manufacturers and saw the opportunity of 3D printing. He did a Google search and came across Northwest Rapid Manufacturing. (And we’re so glad he did!) We’re happy to now be their go-to printer. Every piece of tooling is now printed by us, including the grippers that grab the bottles and set them into the base cup.

The solution for their base cup troubles came in the form of a glass-filled nylon with a rubber liner. In John’s words, they “appear to be holding up well.” The primary source of wear and tear comes from the UV curing process and when the bottles are inserted into the cup. Aside from some color changes, the 3D-printed parts are paying for themselves. On average, a set costs just $35 with a turnaround time of 7 to 10 business days. Parts are now easily and quickly made for new bottle sizes and shapes.

The only tools that we currently can’t replace are those found in another machine used for spray coating. During this process, they’re able to turn brown bottles pink, for example, with the assistance of metal tools. The spray coating gets cured in an oven, and, unfortunately, the 400-degree oven would melt the 3D-printed parts. So, those parts continue to be made of steel.

John’s grandfather started the company with the notion that good relationships are the foundation of good business and explained why he decided on 3D printing.

My grandfather was always very loyal to our vendors. He built relationships with people. Even if we can find a slightly better deal somewhere else, we like the relationship. The flexibility and the ability to come up with something that meets our customer’s needs, price effectively and efficiently.

It makes our little engineering hearts happy to know our 3D printing helps businesses run more smoothly. Have you considered a process in your business where 3D printing can expedite or reduce costs? Let’s talk!

For more information, please don't hesitate to contact us at or request a quote and upload your file today!