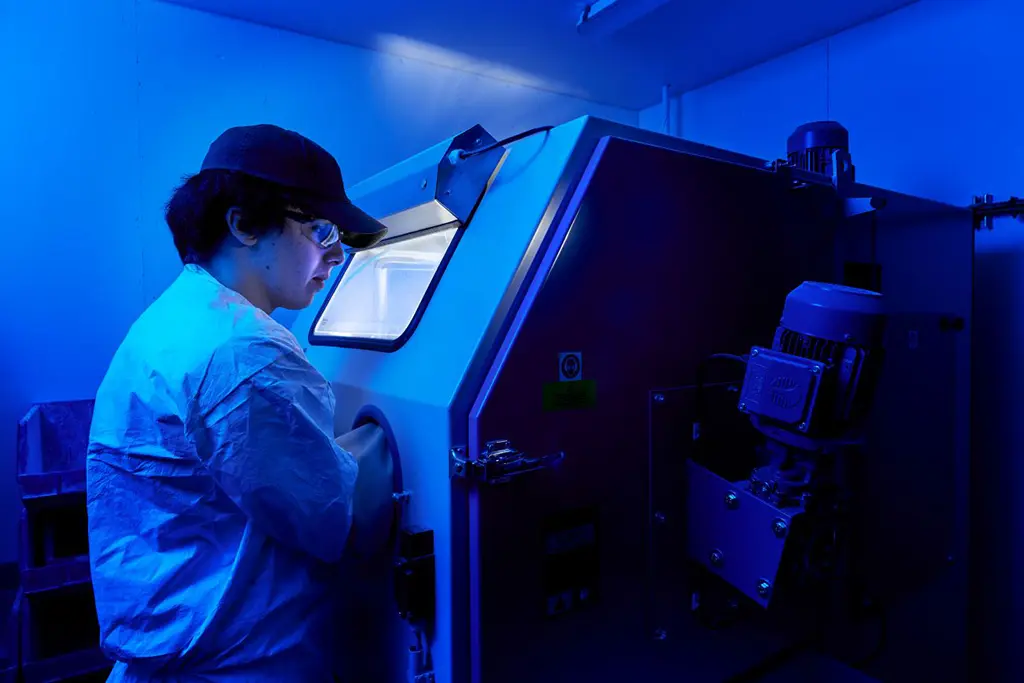

Selective Laser Sintering (SLS) Finishing

SLS Finishing Options

Standard or Smooth Finish

Included in our build price is our standard finish. We bead blast each part to remove any excess powder. Optional vibratory finishing or hand sanding can improve surface texture.

Vibratory Finishing

Smooths and polishes 3D-printed parts by gently tumbling them with abrasive media, improving surface quality and preparing them for final finished.

Fastener Inserts

SLS nylon can be tapped directly for fastener integration. Metal inserts, typically made from brass or stainless steel and available in various shapes and sizes, can be used when additional strength or increased durability is required.

Electroplating & Thin Film Metallization

Copper, nickel, or a combination can be deposited on part surfaces to increase strength or electrical conductivity in shielding applications.

Tank Sealant

Sealant is applied to 3D-printed parts, either internally or externally, to create a leak-proof, chemically resistant barrier, ideal for fluid-handling or airtight applications.

Paints & Dyes

Our 3D SLS parts can be finished with high-performance dyes or painted using Mil-Spec paint formulas to meet demanding industry standards for durability, color consistency, and surface protection.